Evolution of 3D Printing in Manufacturing: Impact & Future Trends

The journey of 3D printing, from its inception in the 1980s to becoming a cornerstone of modern manufacturing, is nothing short of revolutionary. Viewed early on as a tool for rapid prototyping, 3D printing has evolved into a technology that can transform industries by enabling mass customization, reducing lead times, and slashing costs. This progression towards an era where digital designs are seamlessly turned into physical objects has captivated the imagination of innovators and manufacturers alike. Demand for 3D printing continues as companies across the globe recognize its potential to revolutionize the way we conceive, design, and produce goods.

QES Solutions in Rochester, NY, offers trusted 3D printing services. If you need experienced work done, contact us today.

The 3D Printing Revolution

Integration

The integration of 3D printing services into the modern manufacturing sector signifies a groundbreaking shift, making it possible for companies to streamline their development processes like never before. This innovative approach not only can enhance the breadth of manufacturing solutions available but can also catapult firms into the forefront of digital fabrication.

Bridging Prototyping & Production

One of the most transformative aspects of adopting 3D printing technology is its ability to bridge the traditional gap between prototyping and full-scale production. In the past, transitioning from a prototype to a mass-produced model required considerable time, effort, and financial resources due to the need for multiple iterations and adjustments. With the advent of 3D printing, these challenges are substantially minimized.

Accelerating Innovation

This advancement is particularly critical in sectors that demand bespoke solutions or where reducing the time-to-market is of the essence. By leveraging 3D printing, companies can achieve unprecedented levels of customization and agility, facilitating a much smoother and faster progression from concept to finished product.

State-of-the-Art Equipment

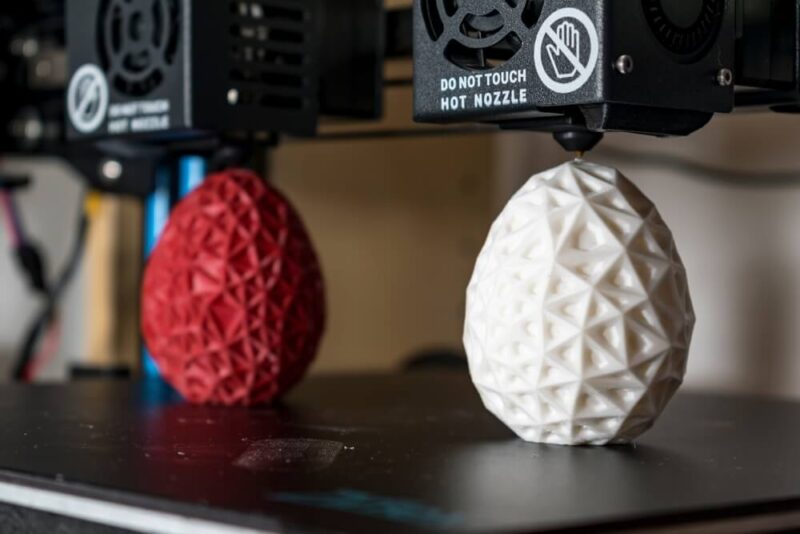

Dual-Extruder & IDEX Printers

Advancements in 3D printing equipment have significantly enhanced the capability and efficiency of manufacturing processes. Among these technological breakthroughs, dual-extruder and independent dual extruder (IDEX) printers stand out as game-changers. These printers allow for simultaneous use of two different materials or colors, drastically reducing the time required for complex jobs and enabling more intricate designs with varied material properties.

Precision Printing Specifications

Precision in 3D printing is crucial for achieving high-quality end products. The latest printers come equipped with enhanced layer resolution and more accurate temperature controls, which are critical for achieving the minute details required in precision components. This capability ensures that every print meets stringent specifications, making it possible to produce parts and products that were once impossible to create with older technologies.

Materials for Every Project Need

Diverse Range of Filaments

The 3D printing landscape is continually expanding and evolving, with a growing array of materials that cater to a diverse spectrum of project requirements. The selection of filaments now available to both hobbyists and professionals is vast, including, but not limited to, PLA, ABS, PETG, TPU, and a myriad of specialty composites enhanced with additives like carbon fiber and metal particles. This variety can broaden the scope of possible application and empower users to select the optimal material to meet the specific demands of their project, whether it be flexibility, durability, heat resistance, or aesthetic finish.

Application & Selection of Materials

Choosing the right material is instrumental in the success of a 3D printing project. Each filament type presents unique characteristics that are tailored to different use cases. For instance, biodegradable options such as PLA are favored for low-impact environmental prototypes, while ABS and PETG are sought after for their strength and heat resistance in functional parts. Additionally, TPU is often used in cases where flexible and robust properties are required.

The material selection hinges on the envisioned application, considering factors such as mechanical performance, thermal stability, and post-processing capabilities. Balancing these considerations can ensure that each project is supported by materials that are best suited to the task at hand, leading to optimal performance and longevity of the printed objects.

Why Choose a Company Like QES Solutions

Expertise & Resources

QES Solutions has established itself as a leader in the 3D printing services. The decision to partner with QES Solutions for your 3D printing needs translates into access to advanced technology, a broad spectrum of material options, and expert guidance from concept through to execution. What sets us apart is our passion for understanding the unique requirements of each project to make sure that clients receive tailor-made solutions that meet or exceed expectations.

Committed to Quality & Innovation

QES Solutions is committed to quality and innovation. Investments in leading 3D printing technologies help QES Solutions offer clients precision, efficacy, and reliability. We are dedicated to leveraging our deep expertise to drive tailored solutions in 3D printing, pushing the boundaries of what is possible and delivering results that embody problem-solving and technical excellence. By choosing QES Solutions, clients are partnering with a service provider that is not only invested in the success of each project but also in the broader evolution of 3D printing technology and practices.

Looking Ahead

The future of manufacturing with 3D printing can mean high efficiency, customization, and innovation. This technology not only reshapes how products are designed and produced; it can also significantly reduce time-to-market and potentially enable more sustainable manufacturing practices. As industries continue to explore these possibilities, the horizon of what can be achieved expands.

Embrace the future today and revolutionize your production capabilities with expert 3D printing services from QES Solutions.